Corona face masks created on a 3D printer

A Ziehl-Abegg employee had by chance been sent a set of build instructions via WhatsApp on the Wednesday evening – and on the Thursday morning Ziehl-Abegg sent a photo of the first face masks to the Crisis Team in the Local Administration Office. Once it gave the immediate go-ahead, both 3D printers went to work at the Künzelsau InVent Development Centre.

“We have been using 3D printing technology since 2010,” explains Achim Kärcher, Laboratory Director at Ziehl-Abegg. The Development Centre already had its second 3D printer by the following year. The cost of a unit is about 100,000 euros. The layers are printed at a thickness of 0.16 millimetres. “We normally use this to create prototypes for implementing new ideas from our engineers,” explains Kärcher. Ziehl-Abegg is a technology leader in biomimetic-based fan design; “so we need to be able to trial new shapes quickly and easily,” adds the Laboratory Director.

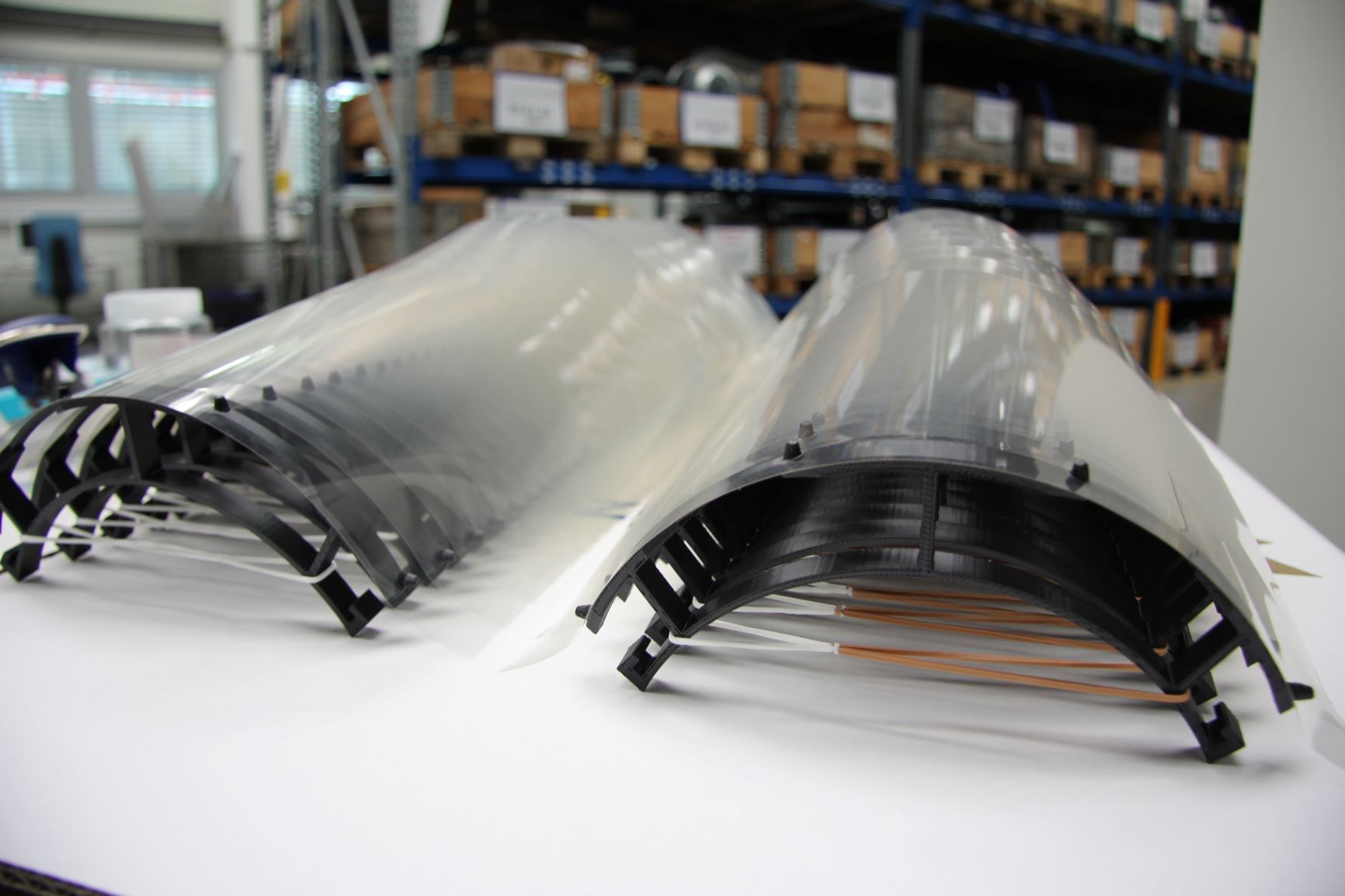

The process of creating the protective masks was also quick and easy: the frame is printed, the lens is a foil for an overhead projector, a standard perforator punches the openings, with rubber bands used for fastening. District Administrator Dr. Matthias Neth says he is also pleased with the “simple but effective” design. He will be passing on the temporary face masks to the ancillary staff in the Hohenlohe district. “We will get through this crisis together and can depend upon on each other,” said Neth. “The District Authority is working in close cooperation with the local companies in the Hohenlohe district,” adds the District Administrator.

“We’re pleased about being able to help employees in the health and care sector in this way” says CEO Fenkl. The medical sector is also part of the company’s normal area of business: for years now, Ziehl-Abegg has been producing large fans for both operating theatres and quarantine stations. The company supplied special fans for Chinese hospitals that were built in the cities of Wuhan, Shandong and Shenzhen within just a few days. The German company also manufactured the core equipment for negative or positive pressure in clinics in Italy and other countries. It is also currently still working at full speed manufacturing these fans in Hohenlohe and worldwide.